Daimler Trucks North America (DTNA) Cables

Sigma Design partnered with DTNA to engineer custom wire harness assemblies tailored for automotive test applications. Sigma Design implemented several solutions to streamline the process including automating testing and custom harness assembly boards.

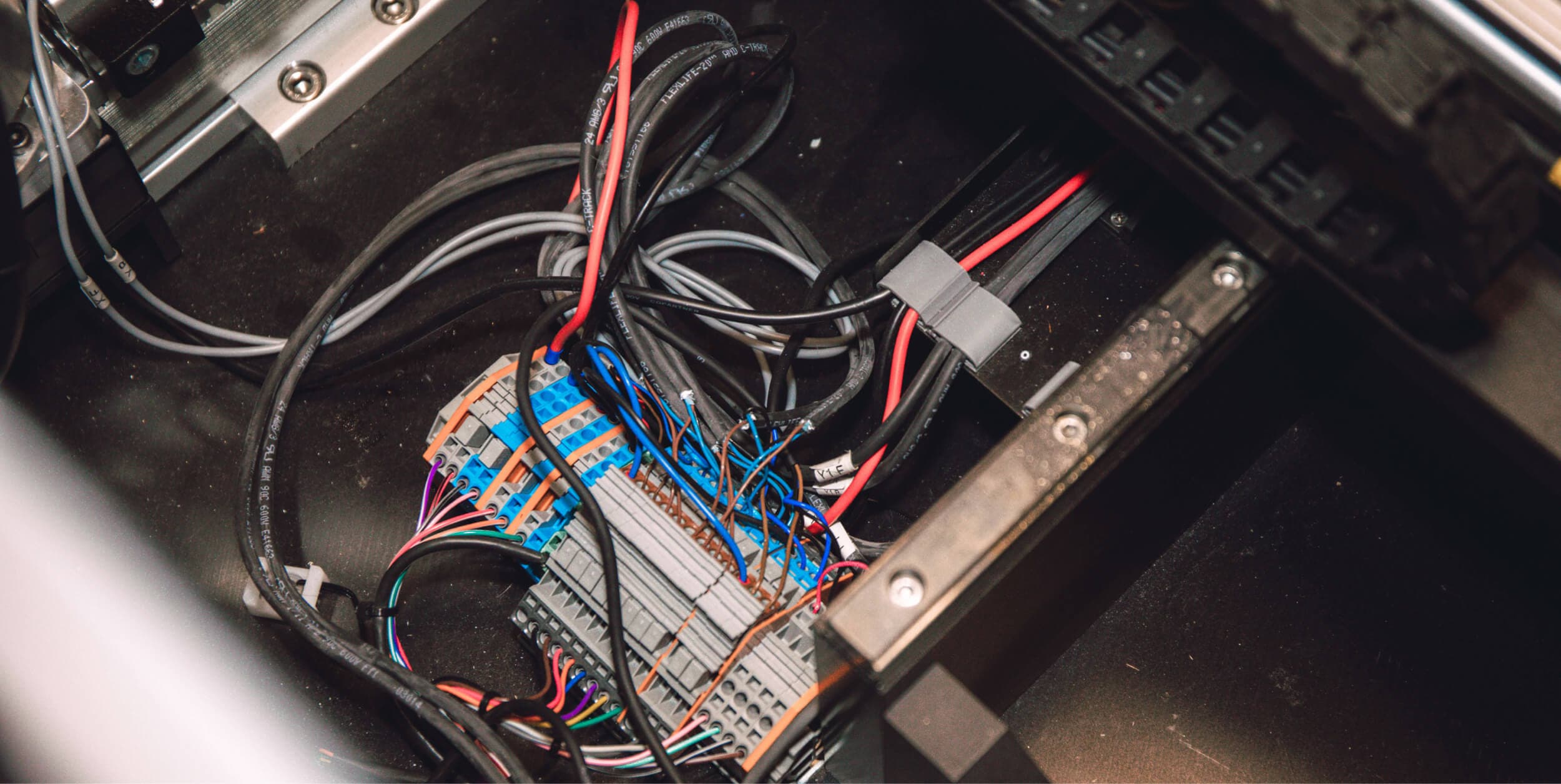

Sigma Design collaborated with Daimler Trucks North America to deliver custom wire harness assemblies designed for their specific needs. The test harnesses, unlike production harnesses, replace standard cable assemblies within test setups, allowing integration of secondary data logging systems. This enables precise monitoring of drive-by-wire systems, much like those found in modern jet planes, leveraging CAN bus control for various vehicle functions.

CAN (Controller Area Network) bus control is a communication protocol developed to enable electronic devices, or nodes within a vehicle to communicate with each other without a central computer. It’s widely used in automotive and industrial applications for its reliability, efficiency, and resistance to interference.

Challenges

Developing these complex cable assemblies presented unique challenges:

- Manual Pin Testing: Initial harness prototypes demanded individual pin testing, which was time-consuming, averaging 3 hours per assembly.

- Adaptation for Component Obsolescence: Throughout the project, DTNA requested design adjustments due to component obsolescence, requiring swift modifications to drawings and systems.

- Complex Cable Layouts: Even at relatively low-volume work, Sigma Design utilized custom harness assembly boards to manage varying cable lengths and connector placements. These large boards ensured precision in wire layout and placement, streamlining the process for complex cable configurations.

Solution & Execution

Sigma Design implemented several solutions to streamline and enhance the process:

- Automated Testing System: Sigma Design made a custom test harness that plugged into an off-the-shelf cable tester. Known good harnesses were then used to “train” the tester. In-house development of this simple solution drastically reduced testing time per cable from 3 hours to under 1 minute. The tester’s capabilities include continuity and short testing, identifying resistance and unexpected voltage between pins.

- Custom Layout Boards: Full-scale layout boards provided a 1:1 guide for assembly, aiding in quality control and reducing errors. These shadow boards allowed Sigma Design to meet high standards in layout accuracy, even with the project’s relatively low production volume (sub-100).

- Specialized Tooling: The project demanded an extensive array of crimpers and hand tools to meet the unique specifications of DTNA’s connectors. Sigma Design expanded its tool library, enabling multiple technicians to work simultaneously and meet project demands.

- High-Quality Standards: Although these harnesses were not built to automotive production standards, Sigma Design followed stringent automotive-level expectations to ensure reliability and performance in testing environments.

Results Summary

- Significant Time Savings: Testing time per harness was reduced by over 98%, from 3 hours to under a minute.

- Enhanced Flexibility: Sigma Design demonstrated agility by adapting designs to account for component obsolescence and continual customer-requested modifications.

- High-Precision Assembly: The use of full-scale layout boards and precise hand tooling led to consistent quality, showcasing Sigma Design’s capability to handle complex, lower-volume projects.

Key Takeaways

Sigma Design’s commitment to quality, adaptability, and innovative use of test automation positions us as a reliable partner for any company needing assistance with custom harness assemblies. Our use of layout boards and custom tooling for low-volume projects highlights Sigma Design’s customer-centric approach, making us an ideal choice for clients with specialized, high-complexity requirements.

Please reach out to us if you'd like to learn more about our cable harness assembly services.